What is Water for Injection? It’s the GRADE water produced through the Vapor Compression Distillation.

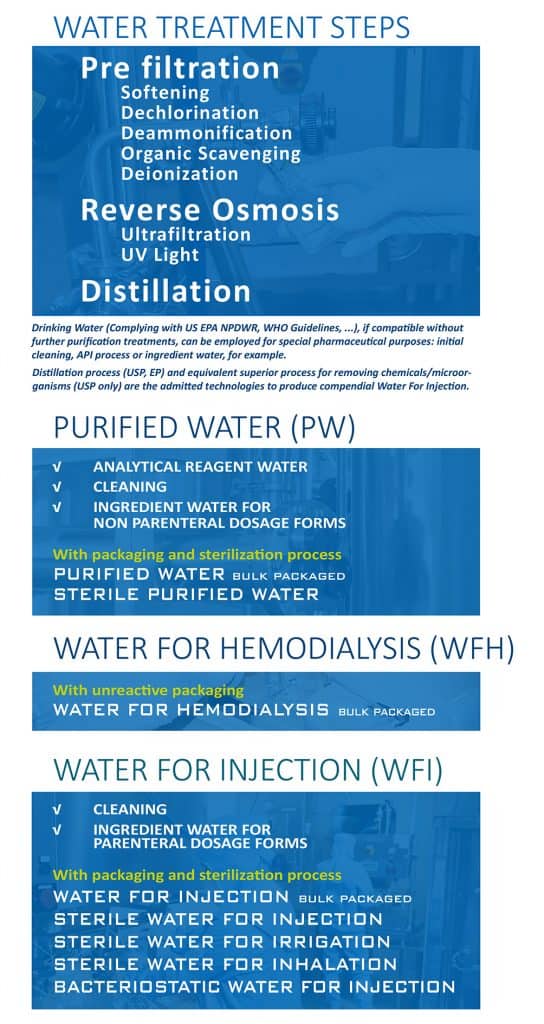

FROM RAW WATER TO COMPENDIAL WATERS

Water is employed as ingredient and solvent in many processes, formulations and products. The International pharmacopoieas (USP, EP, JP) define as “WFI Water For Injection” only the compendial water used as an excipient to parenteral solutions. ISPE Glossary distinguishes:

– Water for Injection in bulk: “Water for the preparation of medicines for parenteral administration when water is used as a vehicle”;

– Sterilized Water for Injection: ” (Water) for dissolving or diluting substances or preparations for parenteral administration before use”.

The finished water meets all the chemical requirements for PW (Purified Water).

At this point, what is Water for Injection? “With an additional bacterial endotoxin parameter” is the specific Water for Injection character. Since endotoxins are produced by microorganisms that are prone to spread in the water, the equipment and the procedures used by the production lines to purify, store and distribute WFI must prevent the build-up of endotoxin. So you can minimize microbial contamination in the system.

DISTILLATION: THE WFI SAFE WAY

The main metod of Water for Injection production is distillation; most pharmaceutical WFI is produced by this system. EP pharmacopoeia admits only distillation as a method for producing compendial Water For Injection. USP pharmacopoeia admits also a “purification process proven to be equal to or superior to distillation”, while JP pharmacopoeia admits, in addition to distillation, the reverse osmosis (RO) plus ultra filtration (UF). However, all three pharmacopoeias pose the same limit for the endotoxine level (0.25 euml), for TOC values, (ppb ≤ 500), for the bacterial load (<10, Colony-Forming Units / 100 mL) and for the value of conductivity (1.3 µS/cm@25°C).

WHAT IS WATER FOR INJECTION. LEARN MORE

At this address (wfi-waterforinjection.com) you can find a complete website about the use of water for injection in pharmaceutical environment. What water for injection means in Europe rather than in Japan or US? Which one is better between vapor compression or multiple effect distillation? There are differences between sterile and bacteriostatic wfi? Reverse Osmosis, Multiple Effect, Vapor Compression, UV treatment: all these technologies are part of our core business. So these pages offer a concrete knowledge of the leading considerations in pharmaceutical field.

As the website home says, “We hope to be useful not only for our customers, but also for the many students asking us questions about the different grades of water used in biotechnologies and pharmaceutical applications”.